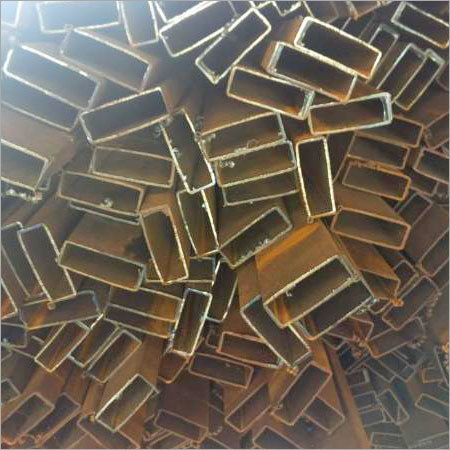

Pipes, Tubes & Fittings

Product Showcase

Recently Added Products

Pipes, Tubes & Fittings - Introduction

Pipes tubes & fittings are used in conjunction awith other fluid control goods such as valves and pumps to form pipelines. In common parlance, "fittings" refers to the end caps that are screwed onto metal or plastic pipes in order to contain the fluids they transport.

Pipes, tubes & fittings come in a variety of shapes and sizes, and they are not limited to just being used to prevent water from leaking when connecting pipes in handrails and other architectural features. Pipe fittings can be attached to pipes in a variety of ways, including welding, threading, mechanical joining, and chemical adhesion.

Different Types of Pipes, Tubes & Fittings

1. Diverter Tee

In pressurized hydronic heating systems, a tee-shaped pipe fitting is frequently used to divert some water from the main line to a branch piped to a heat exchanger.

2. Barb

A barb is another helpful pipe fitting in plumbing; it is used to join movable tubing to rigid pipes. Male threads on one end mate with female threads, and single or multiple barbs on the other end thread into the pliable tubing.

3. Valves

Stopping the passage of water, gas, or air through a pipe requires the employment of valves. There are three main kinds: throttling, isolation, and permanent bans.

4. Wyes

Water can continue to flow smoothly via drainage systems thanks to the Wyes branch line at 45 degrees. When a horizontal connection can't be made with sanitary tees, a wye is required.

5. Bushings

By reducing the bigger fitting to the size of the smaller pipe, these pipe fittings allow pipes of varying Bushings sizes to be joined together. Unlike a union or coupler, bushings don't constantly have the threads facing the wrong way, and they take up far less room while not in use.

6. Butt Weld

Butt weld fittings are the standard that provides the most stability against oscillation. A butt weld that has been properly executed has the highest resistance to noise and wear since the metals are permanently fused together.

7. Push-To-Connect system

To attach the two ends of a tube together, push-to-connect fittings feature an external push button and an inside collet. These fixtures are made from a variety of materials, including polymer, nickel-plated metal, two layers of plastic, and composites.

8. Cons and Threads

As a result of the tube's hard edge and screwless design, the connection between it and the fitting is strong and reliable. After the tube sides have been precisely shaped and polished to a smooth gloss, they must be joined securely against the junction in order to create a watertight seal.

Pipes And Fittings Market Size Report

1. Overview

Rapid urbanization, government investments in infrastructural growth, and the resulting demand for pipes for water distribution systems are expected to propel the pipes and fittings market to $367.9 billion by 2026, at a compound annual growth rate (CAGR) of 3.7% from 2021 to 2026. Large-scale, cross-regional oil and gas projects are largely responsible for the surge in demand for corrosion-resistant steel and plastic pipes with exceptional performance metrics.

2. Segmentation

By Type:

- Glass Pipe

- Aluminium Pipe

- Steel Pipe

- Plastic PVC Pipe

By Application:

- Commercial

- Industrial

- Residential

3. Key Takeaways

The World Bank estimates that by 2020, between 30 and 40 percent of wastewater will have been collected and cleaned for reuse in the United States and its territories. This means there is a growing need for pipes and fittings in the water and wastewater industry for sewage collection and water purification.

On 2019, $4 billion was invested in water infrastructure projects, per an EPA press release. The Pipes, Tubes & Fittings Market for municipal water systems saw a huge uptick in potential because to this funding.

The housing market has been bolstered by rapid urbanization, rising middle-class incomes, and increased private and state investment. Better piping is necessary to secure water supply in these locations, therefore the government should ramp up its efforts to replace older buildings with high-rise ones.

4. Key Players

- Pegler Yorkshire Group

- Anglian Home Improvements,

- Sanitaryware and Industries ltd (Hindware)

- Saint-Gobain

- LIXIL Group Corporation

- Jaquar Corporation

- Kohler Company

Features and Application of Tube Fittings

Key Features:

- Precise dimensions, as opposed to nominal specs, are typically used to define tubes and their fittings.

- There are many structural uses for tubes, and the outside diameter is typically employed to determine their size (OD). Pipes are often used to transport fluids from one location to another, with the internal diameter serving as the primary sizing factor (ID).

- Correct size is the most fundamental feature of tube fittings, and it can be fixed.

- When operating, pressure and temperature are the two most important criteria for securing tubes

- Materials for tube fittings are often selected in tandem with tubing materials.

- The decision is influenced by a number of factors, including price, adaptability, media, environmental factors, and required pressure ratings. A variety of metal and plastic varieties are offered.

Applications:

Since the structure and material requirements of fittings are application-specific, it is usually a good idea to visit a fitting supplier in order to optimize component selection. In contrast, tube fittings are typically seen in hydraulic or pneumatic systems. Locating the fundamental system type is the first step in selecting the most suitable fits for the application.

Fluids like water and various chemical solvents are transported in hydraulic applications. In addition to being chemically and rust-proof, hydraulic fittings must be able to seal against leaks of liquid.

Pneumatic functions are used for transporting gas. In order to prevent gas leakage, pneumatic fittings need to have very tight seals and be chemically resistant.

There are several uses for tube fittings in the construction industry. The fittings must have high physical integrity but no sealing requirements because they do not carry fluids.

What are the 4 Types of Fittings?

1. Valves

The intricacy and variety of valves means that they are sometimes classified as a separate category, despite the fact that they are technically fittings.

Valves come in a wide variety of shapes and sizes, but they all serve the same purpose: regulating the flow of liquids and gases. Some valves can even be adjusted to regulate the temperature.

Butterfly, gate, globe, and ball valves are some of the most popular varieties. The most prevalent kinds of valves are those found in sinks and showers/tubs.

2. Elbows

The ell, or elbow, is a fitting used to redirect the flow of a pipeline. While 45 and 90 degree angles are the most common for an elbow's bend, other angles are possible. Elbows are available in a wide range of diameters and are often threaded for easy assembly.

The extension of your shower's wall to which the shower head attaches is a common example of an elbow fitting in the home.

3. Tees, Crosses and Wyes

Pipes and tubes can be joined or separated using a tee, wye, or cross fitting. The names of these structures reveal something about their essential structure: One input can lead to two different outlets (or vice versa) in a tee or wye fitting, while a single input can lead to three different outlets (or vice versa) in a cross fitting.

All three types are available in both uniform (all outlets/inlets are the same size) and decreasing (one or more outlets/inlets are a different size) configurations.

4. Couplings and Unions

There is a wide range of sizes and styles available for couplings and unions. Each serves primarily to join together two lengths of tubing or pipe.

As a result, couplings and unions are often fairly brief fixtures. Couplings are intended to be permanent and are usually welded in place or fastened with a series of bolts and nuts, whereas unions are intended to be removed at will.

Each tube fitting has two essential jobs to do within the range of its operating pressure, temperature, and vibration. Below, we provide some examples of the different kinds of pipe fittings that fall into the aforementioned categories. The primary function of the tube fitting is to prevent the tube end from becoming unsealed or blown out. The tube's fitting must also provide a reliable secondary seal. Get the pipe fittings you need from the best companies in India today!

FAQs: Pipes & fittings

Q. Where are Pipe Fittings used?

Ans. An assortment of pipes of the same or different diameters can be joined together with the help of a pipe fitting, which can also be used to control the water flow or to monitor its intensity.

Q. Is Pipe more Expensive than Tube?

Ans. Pipes often have a lower total cost due to their cheaper production price as compared to tubes.

Q. What is Difference Between Pipes and Tubes?

Ans. A tube typically has stricter engineering criteria than a pipe does, although otherwise the two phrases can be used interchangeably. Pipe and tube both connote a degree of rigidity and permanency, while a hose is typically mobile and adaptable.

Q. What are Different Types of Pipe and their Uses?

Ans. Here are some types and their uses:

- Cast Iron Pipe: It is used for water distribution system

- Galvanized Iron Pipe: it is used to supply water, gas or liquid

- Wrought Iron Pipe: It is used to carry water, gas or liquid

- Steel Pipe: Carry out water, gas or liquid

- Copper pipe: Carry hot water or Steam